The workshop delves into the cutting-edge intersection of technology, sustainability, and industrial transformation. As businesses prioritize sustainability

alongside increased productivity, there’s a reevaluation of material usage and recycling methods. We’ll explore applications in battery, fashion, and composite material recycling, showcasing how Robotics and AI are shaping diverse sectors. Talks will cover technical and business viewpoints, offering insights into challenges and opportunities in sustainable production. Stay updated with the latest advancements in recycling and remanufacturing, and discover how Robotics and AI are shaping the future of these industries.

Location: European Robotics Forum 2024 in the Palacongressi di Rimini, Via della Fiera, 23, 47923 Rimini

Date and Time: 15 Mar 2024 08:30-09:50

Key Research Questions:

- Unleashing the Potential: What are the current applications of robotics and AI in recycling and remanufacturing, and how can these technologies revolutionize sustainable production?

- Tackling Challenges: What are the primary challenges that robotics & AI can address in recycling and remanufacturing, and what barriers hinder their adoption for sustainable practices?

- Balancing Act: How can we overcome these challenges and barriers to integrate robotics & AI into recycling and remanufacturing processes, considering technical, economic, environmental, and social aspects?

Approach and Agenda:

The workshop will follow a structured approach, divided into two parts, each approximately 40 minutes long. We will kick off with insightful impulse talks from five keynote speakers, representing both academic research and industry expertise. Following this, we’ll engage in a panel discussion with industry and academia experts, along with active participation from the audience. Throughout the session, we’ll employ interactive tools such as Mentimeter and Polls to foster dialogue and gather diverse perspectives. The workshop will conclude with summarizing remarks from the organizers and the dissemination of findings through a position paper.

Workshop Agenda:

- Opening comments by the organizers (5 minutes)

- 5 Impulse Talks (end-users/Tech Providers/academia) (40 minutes)

- Panel Discussion (4-6 speakers as panelists) + Audience Interaction (35 minutes)

- Concluding remarks by the organizers (5 minutes)

Confirmed Speakers:

- Agata Suwala, MTC, UK

- Michael Hofmann, Profactor GmbH, Austria

- Gianmarco Griffini, Politecnico di Milano, Italy

- Kat Thiel, Manchester Fashion Institute, UK

- Konstantinos Kokkalis, ICCS, Greece

Invited Talks

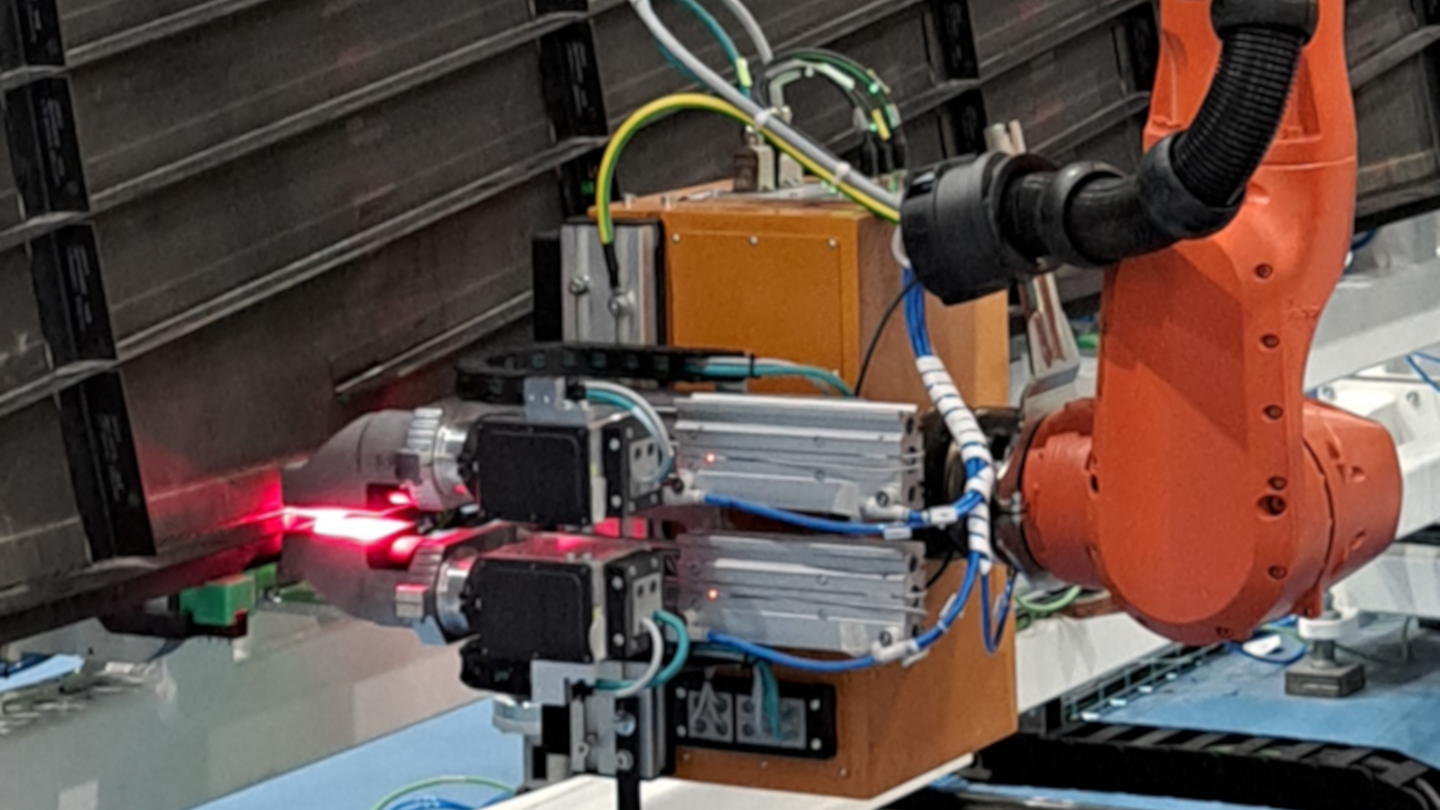

Speaker: Hofmann Michael

PROFACTOR GmbH, AT

Title: On re-use of lithium-ion batterie cells using assistive robots in low volume high mixture use cases

The high acquisition costs for lithium-ion batteries (LIBs) are considered one of the biggest obstacles to the introduction of electric vehicles on the mass market. Aged traction batteries sometimes no longer meet the high requirements for power and energy density in EV applications. Secondary use is a possible solution to reduce the acquisition costs of electric vehicles and extend the useful life of the batteries. This opens up opportunities to generate additional revenue and improve the eco-balance of electromobility but requires novel maintenance and re-use processes and thus motivates their automation. The talk will summarize motivation and challenges as well as introduce solution strategies as well as intermediate results in ongoing research.

Speaker: Gianmarco Griffini

Speaker: Gianmarco Griffini

Politecnico di Milano, IT

Title: Reuse, remanufacturing and recycling technologies for enhanced circularity of fiber-reinforced composites

The steady growth of the EU composites market together with an increasing demand for high-performance fibrous material (especially carbon) at affordable costs in many manufacturing sectors call for the development of innovative reuse, remanufacturing and recycling technologies able to penetrate key industrial value chains. In this talk, novel technological approaches to boost the circularity of composite materials will be discussed, with an outlook on their potential social, environmental and economic impact.

Speaker: Kat Thiel

Speaker: Kat Thiel

Manchester Metropolitan University, UK

Title: Fashion Practice Research for Collaborative Automation

The Robotics Living Lab (RoLL) is a new fashion research facility at Manchester Fashion Institute at Manchester Metropolitan University. Opening in summer 2024, RoLL will conceive, test, and develop new robotic tooling solutions for innovative manufacturing processes and enable new research into highly responsive sustainable approaches for garment manufacturing. RoLL aims at developing agile robotic systems and user-friendly tools, enabling designers to offer world-class fashion design products that, crucially, are locally manufactured

Speaker: Fotis Konstantinidis

Speaker: Fotis Konstantinidis

National Technical University of Athens, GR

Title: Utilising Multi-sensor cyber-physical sorting system (CPSS) in waste facilities

Products global demand constantly grows, along with drifts of the volume of waste produced, thus having a negative impact on the environment. Besides the advancement of artificial intelligence and cutting-edge sensing and actuation systems, allow for traditional recycling procedures to be digitised and become more efficient. Among these, automated sorting machines allow such efficacy, by using multiple recognition technologies to categorise items, instead of relying on humans to separate them. In this sense, a new approach being included in the Cyber-Physical Sorting System (CPSS) capable to be adapted in different industries such as urban wastes, construction & demolition wastes as well as mineral sorting will be analysed. The materials are laid out over a conveyor belt, where multi-purpose visual sensors (hyper-spectral, industrial and short-wave infrared) acquire images in order to classify and sort them in different bins using robotic arms.

Speaker: Agata Suwala

Manufacturing Technology Center, UK

Title: The tipping point – automation and robotics for circular economy

With the widespread adoption of automation and robotics technologies within the sustainability space there are new considerations that need to be addressed. Current products have not been designed with re-use in mind but with planned obsolescence. How do we support the transition both for the current products but also the once that haven’t been designed yet.

Related Insight Session: Robotics & AI: Transforming Sustainable Recycling & Remanufacturing

Date: 15th March 2024

Time: 14:45 – 16:05 CET

As part of the Robotics & AI Workshop on Transforming Sustainable Recycling & Remanufacturing, we are thrilled to announce a dedicated insight session featuring seven selected papers. This session provides a platform for authors to present their cutting-edge research and insights related to the workshop theme.

Instructions to Authors: Authors presenting at the insight session are kindly requested to adhere to the following guidelines:

- Each presenter will have a strict 4-minute slot for their oral presentation.

- Presentations will follow a pitch format, focusing on succinctly conveying the main results of the paper.

- Following the pitches, there will be an interactive poster session, allowing ample opportunity for discussions with the authors.

- Authors must prepare both a 4-minute pitch presentation (using slides or videos) and a poster (70 x 100 cm) detailing the contributions of their work.

- For those interested, on-site printing services for the poster are available. Please contact erf2024.program@nullaimgroup.eu for further details

Schedule:

14:50 – 14:54

DemoDatenPro: Methods for semi-automatic disassembly and data acquisition in circular economies

Michael Hofmann, Matthias Propst, Markus Ikeda and Andreas Pichler

14:54 – 14:58

A Flexible Robotic-based Architecture for Cyber-Physical Sorting Systems in Waste Management IndustryKonstantinos Kokkalis, Fotios K. Konstantinidis, Georgios Tsimiklis and Angelos Amditis

14:58 – 15:02

Towards Measuring the Ease of Robotic Disassembly

Christoffer Sloth and Iñigo Iturrate

15:02 – 15:06

Robotic ease of Disassembly Metric (Re-DiM) for flexible cooperative re-manufacturing of bike batteries

Terrin Pulikottil, Wouter Sterkens, Mathijs Piessens and Jef R. Peeters

15:06 – 15:10

Cognitive and robotic assistance to increase efficiency in Li-ion battery re-manufacturing

Matthias Propst, Michael Hofmann, Markus Ikeda and Andreas Pichler

15:10 – 15:14

Navigating Sustainability: A Real-world Examination of Life Cycle Assessment in Early-Stage Robotics

Paula Preu and Michel Joop van der Schoor

15:14 – 15:18

Multi-modal Electronics State Evaluation for Robotic Demanufacturingù

Yifan Wu, Chuangchuang Zhou, Wouter Sterkens and Jef Peeters

15:18 – 15:22

Portable, Robotic Material Recovery in a Box

Michail Maniadakis, Antonios Liapis, Jef Peeters, Vasilis Makridis, Laurent Paszkiewicz, Fredy Raptopoulos, Javier Grau Forner, Myrto Pelopida, Friederike Kleijn and Nikos Vythoulkas

15:22 – 15:26

Robot Design with Sustainability-Impact-Based Requirements

Michel Joop van der Schoor

15:26 – 16:10

Interactive Poster Presentation

Interactive Poster Session:

Following the pitch presentations, attendees are invited to engage in an interactive poster session. Authors will be available to provide detailed explanations and insights into their research findings. This session aims to foster networking and collaboration opportunities among participants.

Organizers:

- Sharath Chandra Akkaladevi, Profactor GmbH

- Franziska Kirstein, Blue Ocean Robotics

- Karol Janik, Manufacturing Technology Centre (MTC)

Join us as we explore the cutting-edge intersection of robotics, AI, and sustainability, and discover how they are shaping the future of recycling and remanufacturing industries. Don’t miss this opportunity to be part of the dialogue driving positive change towards a more sustainable future!

PROFACTOR will be presenting innovative solutions for quality assurance, digitalization and automation for flexible and efficient production.

PROFACTOR will be presenting innovative solutions for quality assurance, digitalization and automation for flexible and efficient production.

Speaker: Gianmarco Griffini

Speaker: Gianmarco Griffini Speaker: Kat Thiel

Speaker: Kat Thiel Speaker: Fotis Konstantinidis

Speaker: Fotis Konstantinidis

DI Dr. Michael Mühlberger

DI Dr. Michael Mühlberger