The increasing shortening of product and innovation cycles as well as the increasing volatility of the markets require that production systems have to be adapted to the actual situation more than ever before. While factory planning and system design still have a great deal of freedom in terms of the adaptation of structures and layout, the options during operations are focused primarily on production planning and control. The aim is to use the existing production infrastructure as best as possible for the upcoming orders and to reconcile the actual point of operation with the requirements.

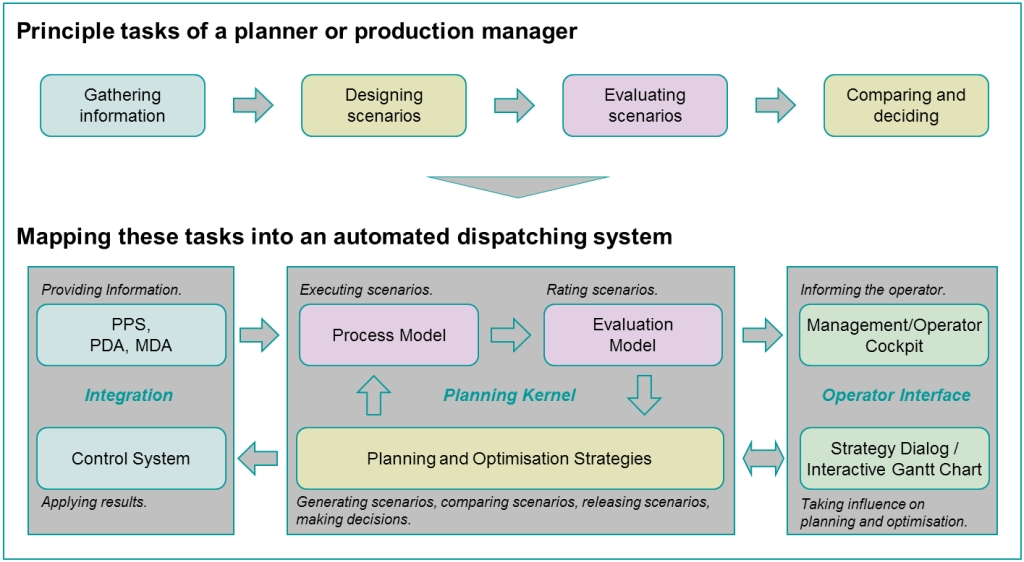

For this purpose, PROFACTOR expands the simulation models of factory planning in order to make them available to day-to-day operations. For this purpose, the models must be matched with the reality, as well as initialized with the respectively current system state. This requires appropriate interfaces to existing IT systems and user interfaces. The spectrum ranges from simple stand-alone planning solutions to integrated, simulation-based optimisation.

A special focus is the control of volatile production systems with strong stochastic influences by means of priority rules (dispatching rules). These priority rules are developed and optimised using simulation models. In the day-to-day business, the simulation models provide a preview of the expected production sequences as well as for the key performance indicators to be expected. This supports planners and dispatchers in their day-to-day work, reduces the planning effort and increases system performance.

Research projects investigate how the priority rules can be created and optimised automatically using metaheuristic optimisation methods. For this purpose the desired production strategies are defined by extensive rating models. If necessary, these rating model take into account not only economic indicators (e. g. utilisation, inventory, deadlines), but also environmental (e. g. energy consumption, consumption of materials and auxiliaries, residual quantities, noise) and working psychological / economic indicators (e. g. stress, work monotony, satisfaction).

Range of services:

- Development of specific solutions for production control (Advanced Planning & Scheduling): strategies for order scheduling, order clearance and order control; robust priority / dispatch rules for volatile, stochastic systems; sequencing; lot size optimisation; planning and assigning of resources.

- Data analysis / visualization / integration: Integration, preparation and evaluation of machine and operating data from various sources for analysis and decision support as well as input for the forecast models.