Ever increasing quality requirements, a broader product diversity or stronger competition are important drivers for digitalisation and the optimization of operational procedures.

For many tasks in manufacturing and the service sector workers are superior over automated solutions. Examples are: complex assembly procedures, manual quality checks or tasks requiring high flexibility.

Modern assistance systems support workers directly at their core tasks and therefore combine manual and digital work steps.

PROFACTOR has extensive experience in the development and application of digital assistance systems.

- In Manufacturing: digital assistance and Industrial Augmented Reality for quality assurance for conveyer belt situations and for manual work places.

- In the health and rehab sector: video based analysis and documentation for quality assurance of therapy procedures.

Our assistance systems in general have a cognitive functionality and recognize movements of humans or objects through sophisticated camera technology and software (see also our AssemblyEye video.)

These technologies are applicable in many different fields. We are open to hear your application ideas and requirements.

We strengthen your quality through digital assistance. Talk to us.

Solutions

Digitization & Assistance for Quality Assurance

Digital Sorting and Order Picking Assistant

Other Solutions

The PROFACTOR proprietary development ReconstructMe models workspaces, people, objects and assembly parts in real-time. The software is thus the basis for various industrial and commercial applications:

The PROFACTOR proprietary development ReconstructMe models workspaces, people, objects and assembly parts in real-time. The software is thus the basis for various industrial and commercial applications:

- Assistive robotics

- Orthopedics

- Fashion

- Architecture

- Construction Plants

- Accident Forensics

The advantages of this PROFACTOR-solution:

- Hardware independence: all standard RGBD sensors (i.e. 3D cameras) can be used.

- Application independence: A software development toolkit is available and is configurable for further development.

- Texturing: The vertices of the model are fused with the color information resulting in a common 3D model. This makes color models possible.

- Intelligent filling: Non-observable “occluded” points are intelligently filled by the algorithm.

- Export: The data can be exported to popular CAD formats.

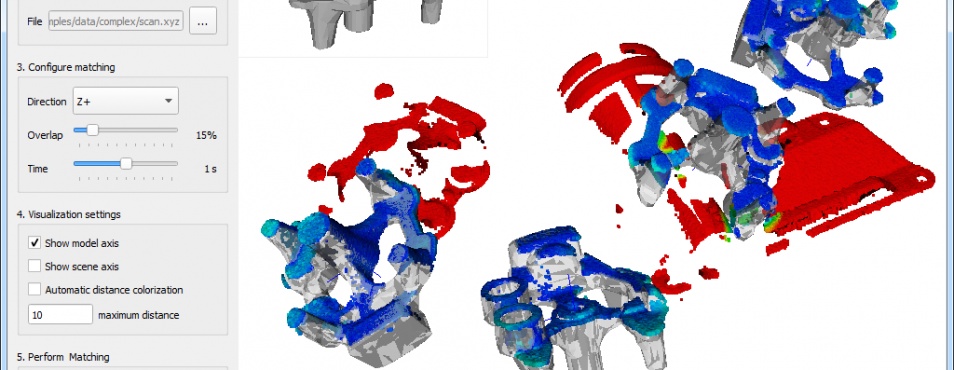

The PROFACTOR proprietary development Candelor recognizes CAD-defined objects in “noisy” environments – for example in unsorted crates.

The PROFACTOR proprietary development Candelor recognizes CAD-defined objects in “noisy” environments – for example in unsorted crates.

The solution allows a wide range of applications in the industry:

- Bin Picking

- Robotic: Screwing and Handling assistance

- Completeness monitoring

- Visualization: together with Augmented Reality solutions

The advantages of this PROFACTOR solution:

- Sensor Independence

- Flexibility: Performance versus Repeatability is configurable

- Standalone testing with the help of graphical user interface

A tool for real-time 3D tracking (in high frequency) is currently under development.