Micro- or nanostructures on a surface can significantly improve components, enable new functions or achieve unique aesthetic effects.

PROFACTOR has more than 15 years of experience in technology development and the application of nanoimprint lithography (NIL), a cost-efficient, high-precision technology for the replication of micro- and nanostructures.

We are your partner for the micro- and nano-structuring of rigid and flexible materials. We support you from first demonstrators and process development to small series production and the transfer to mass production.

In many projects with our customers we have been able to demonstrate our expertise through successful process development or small series devices manufacturing.

Talk to us. We speak nano.

Applications

Micro-Optics

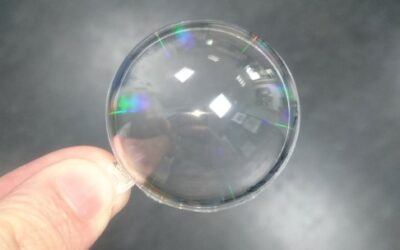

Using nanoimprint lithography, micro-optical elements such as micro-lenses, micro-mirrors or waveguides can be produced cost-effectively and with highest precision.

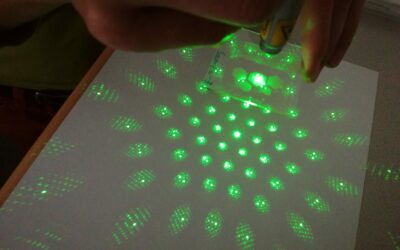

Nano-Optics

Diffraction-optical elements or meta-lenses open up unimagined possibilities for manipulating light.

Nanoimprinting is the ideal manufacturing method for this.

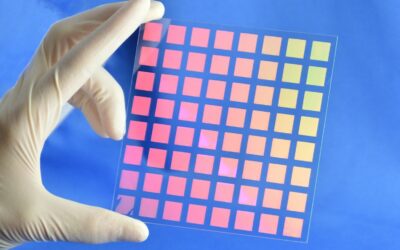

Jewelry

With refractive or diffractive optical elements, you can achieve unique aesthetic effects on your products such as watches, jewelry, life style accessories.

Decoration that makes your customers shine.

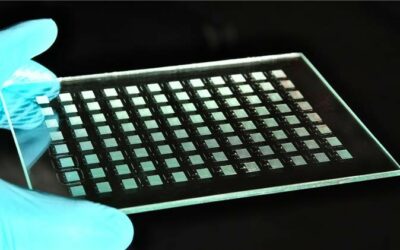

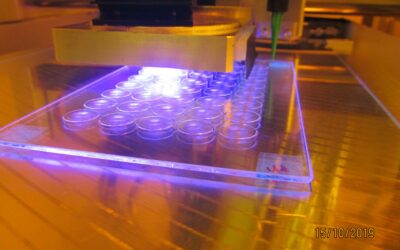

Life sciences

Micro- and nanostructures can be used in many different ways in life sciences applications. Antimicrobial structures, surfaces for the growth of specific cells through to microfluidic systems or plasmonic sensors are just some of the applications.

Nanoimprinting allows to directly structure functional (e.g. biocompatible) materials on a variety of substrates.

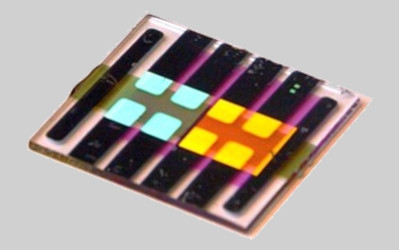

Augmented Reality (AR)

Augmented reality is an important technology of the future.

Nanoimprinting is THE technology for producing optical waveguides for AR glasses cost-effectively and in high quality.

Anti-reflective structures

Glass or polymer lenses often have poor optical transmission properties due to surface reflections.

Nanostructures for reflection reduction (such as in moth-eyes) can significantly increase the transmission properties of optical elements and thus significantly improve the efficiency of optical systems.

Light guiding

Compact light guiding elements based on micro-optics or diffractive optics offer the possibility of efficient lighting that reduces both light pollution and energy consumption.

Nanoimprinting offers a sustainable, energy-efficient way of producing such structures at low cost.

Solar energy

Nanoimprint lithography offers a wide range of possibilities, from plasmonic to biomimetic effects, both for light management in solar cells and in modules.

Technologies

Roll-to-plate (Roll2Plate)

In addition to the fast and cost-effective application of micro- and nanostructures, users also benefit from the highly flexible process with regard to substrates, materials and sizes and shapes of structure.

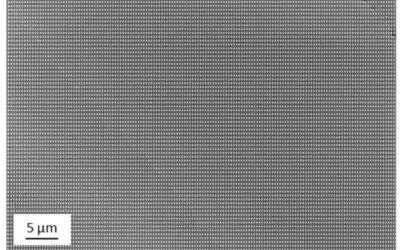

Step & Repeat

We are able to reproduce a small-sized structure over a larger area using Step & Repeat NIL and thus realize large-area and cost-effective imprint processes.

Solutions

We are happy to support you in your projects with high-quality NIL prototypes and processes.