In a cyclic production line, crack checking can be done by laser heating and heat-flux evaluation. If the specimen doesn’t move, a pattern of laser points is heating up a surface area simultaneously, while a thermal camera records distribution and evolution of the surface temperature. Evaluation is then looking for discontinuity in the temperature profile, which indicates a crack. In case of continuous movement of the specimen, the surface is simply scanned by the laser spots.

Application:

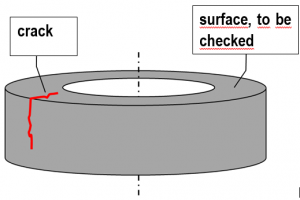

A specimen, which is rotationally symmetric shall be checked for cracks at its top surface by laser induced heat flux thermography.

A specimen, which is rotationally symmetric shall be checked for cracks at its top surface by laser induced heat flux thermography.

The cracks are going from the surface into the material, and are orientated randomly. At the surface they can be closed, so that even with a microscope they are not visible.

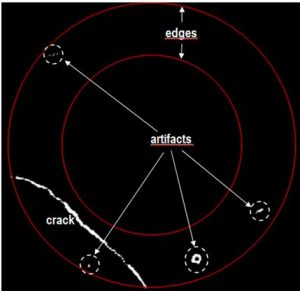

While the specimen is turning, the checking system scans its entire top surface. The results of each single scan cycle then will be assembled into an image of the specimen, containing the crack information.

While the specimen is turning, the checking system scans its entire top surface. The results of each single scan cycle then will be assembled into an image of the specimen, containing the crack information.

Properties of the checking system:

- One part is checked in 2.6s

- Checking system is fully encapsulated

- Feed and removal of specimen by conveyor belt

- Parts with cracks are removed from production line