In case of specimen with a more complex geometry, a robot is used to handle such parts, and to scan the surface for cracks.

Based on the CAD-data, the controllin g unit calculates an optimal path, which is then implemented by the robot to check the entire area. The evaluation unit sends the crack locations back to the controlling unit, which checks, if the entire area was checked.

g unit calculates an optimal path, which is then implemented by the robot to check the entire area. The evaluation unit sends the crack locations back to the controlling unit, which checks, if the entire area was checked.

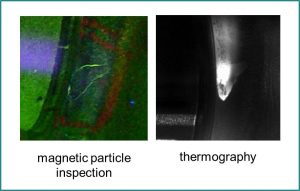

Thermal images show cracks somewhat different in relation to the well-known MT-Method, but the information about the crack is contained in both of them. In the thermal application the detected cracks are drawn into the image or into the CAD-model, to achieve a display, which is better understandable.