The specimen is transported by a conveyor belt, passing an array or Xenon-spots, which act as a heat source. An array of heated lines, distributing their heat to each side is the result.

If there is a crack located in the path of the distributing heat, a discontinuity in the temperature profile will appear in the thermal image, which is identified by the evaluation unit as being a crack.

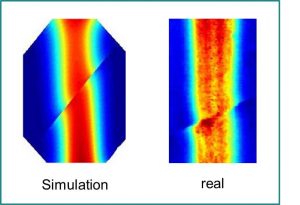

Both thermal images show a typical temperature distribution in case of a crack.

Evaluation is based on comparison of reference profile with the actual profile and by searching for steps in the distribution.

If there is a crack located exactly in the heat-line, and if it is orientated in the same direction as the line, it can’t be detected by this checking system. Alternative methods, like for instance pulsed heat source or evaluation of the heating up have to be implemented in such case.

Properties of the system:

- fully automated

- no additional handling necessary

- can be applied to specimen with medium thermal conductivity

- specimen must have a flat surface