The project NEAT will bring forth a cost-efficient fabrication process for advanced nanoelectrode arrays suitable for (automatized) drug-screening using tissue models grown on a chip.

Advanced cell array technologies (e.g. multielectrode arrays (MEAs) or planar patch-clamp) have emerged as novel standards for studying in vitro cardiovascular, neurological and other diseases and for developing novel drugs to treat them. The application of these technologies to human stem cell-derived tissues enables drug discovery and drug safety studies on human preparations. It is well established that cardiac and non-cardiac drugs can induce prolongation of the Q-T interval of the ECG and cause arrhythmias. Screening for cardiotoxic drug effects became, therefore, part of the routine process in drug development and a requirement of regulatory authorities. The estimation of the pro-arrhythmic effects of drug candidates can reduce risk, time and costs for companies and represents for the consortium a specific use case to demonstrate the capabilities of the proposed approach.

NEAT project addresses the principle disadvantages of standard cell array technologies:

- current cell cultures represent native tissues only rudimentary,

- the extracellular electrodes of chip arrays do not provide absolute values of resting and action potentials compared to gold standard intracellular microelectrode or patch-clamping techniques and,

- cell contractions of mature myocardial preparations lead to movement artifacts and cell detachment.

The consortium aims at overcoming these limitations by means of the nanofabrication based on nanoimprint lithography (NIL) of new chip configurations. It is anticipated that this novel array technology will substantially facilitate drug discovery and drug safety studies on myocardial, neuronal and other cells in the pharmaceutical industry.

During the project duration, the Roll to Plate lab system available at Profactor will be upgraded to implement inkjet printing, scraper arrangements as well as drying units, which will increase the versatility of the system.

One critical part to obtain a cost-efficient fabrication process for NEAT will be the use of the Soft Stepper C-1-1-Y developed at Profactor for the fabrication of printing plates. Some of the highlights of the system are:

- Up to 360 imprints per hour (depending on the materials)

- Ideal for material testing and lab-scale imprinting

- High power UV-LED module

- Vacuum table for easy fixing of the substrate

- Maximum substrate size 150 x 150 mm2

- Stage movement (x-y-z): 300 x 200 x 50 mm

- Stamp size up to 1.5 x 1.5 cm2

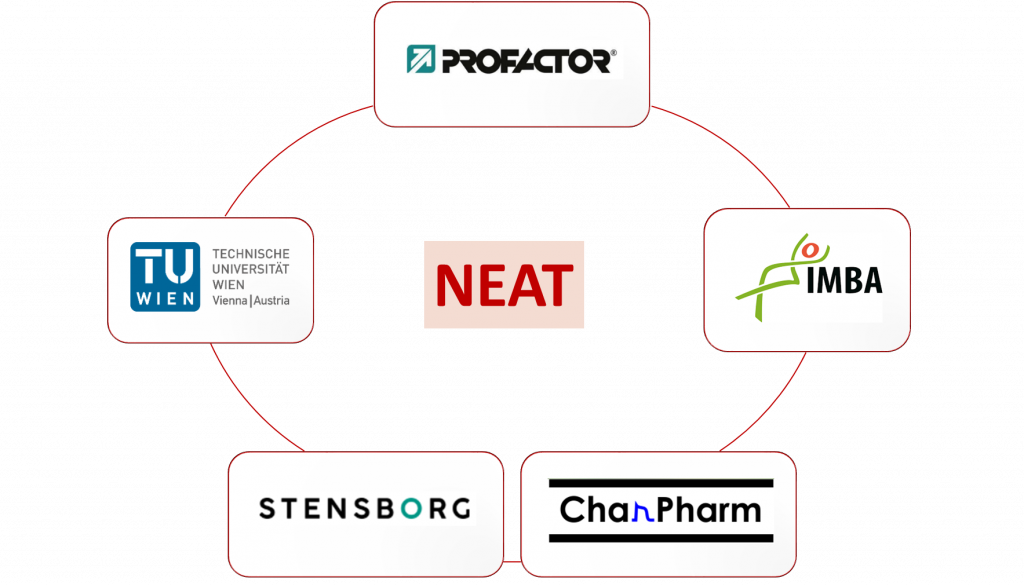

Profactor is the coordinator of the project, and the consortium is completed with two research institutions, the Institute of Solid Electronics at Technical University Vienna (TUW) and the Institute of Molecular Biotechnology (IMBA), and two companies, ChanPharm GmbH and Stensborg A/S. The consortium covers all the scientific and technical competencies needed for the project and provides the perfect scenario to assure the success of NEAT project.

Project Name:

Nano Electrode Arrays for stem-cells derived Tissues

Funding:

FTI-Initiative Produktion der Zukunft

Duration:

01.04.2019 – 31.03.2022