Fiber analysis through advanced machine vision

The growing demand on high strength and lightweight structural parts in applications such as aerospace, automotive, etc. requires a robust quality control technology to guarantee strength and optical quality of parts. One of the critical success parameters in carbon and glass fiber composite parts is the correct fiber orientation. For such automated inspection the method of choice is optical measurement.

Carbon fiber materials appear either black or shiny bright, depending on the illumination direction. These complex reflection properties therefore pose severe difficulties to standard quality inspection technology based on conventional image processing.

Solution

The F-SCAN inspection system allows an accurate measurement of fiber orientation on carbon and glass composite parts by using directional illumination and an elaborate reflection model. Robust analysis of positions and orientations of fibers allows the automatic detection of typical defects such as inclusions or distorted fabric.

The technology can be used during different stages of the manufacturing process. Starting with the inspection of raw fiber material, the measurement of fiber orientation of the preform part and finally for quality control of the clear-coated part.

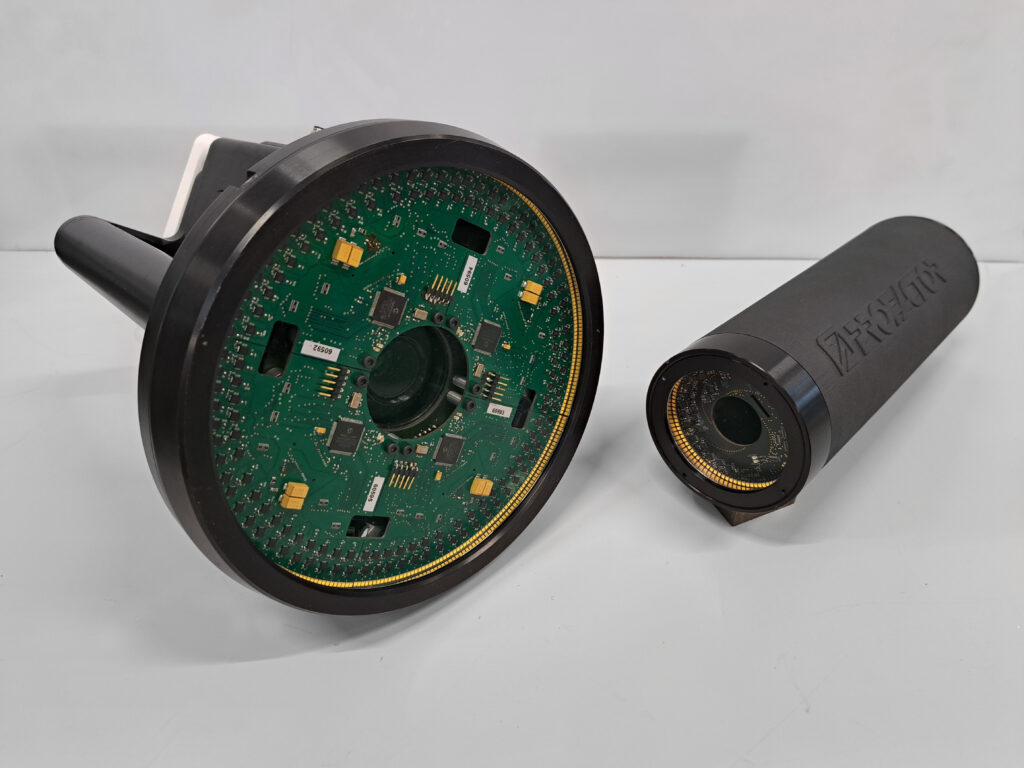

F-SCAN Standard

The standard sensor is designed for fast scanning of low curvature fiber composite surfaces.

Resolution: 40-60µm

Measurement speed: 1m/s

Sensor width: 200 x 200mm

Sensor length: 300mm

Field of view: 50 x 50 mm

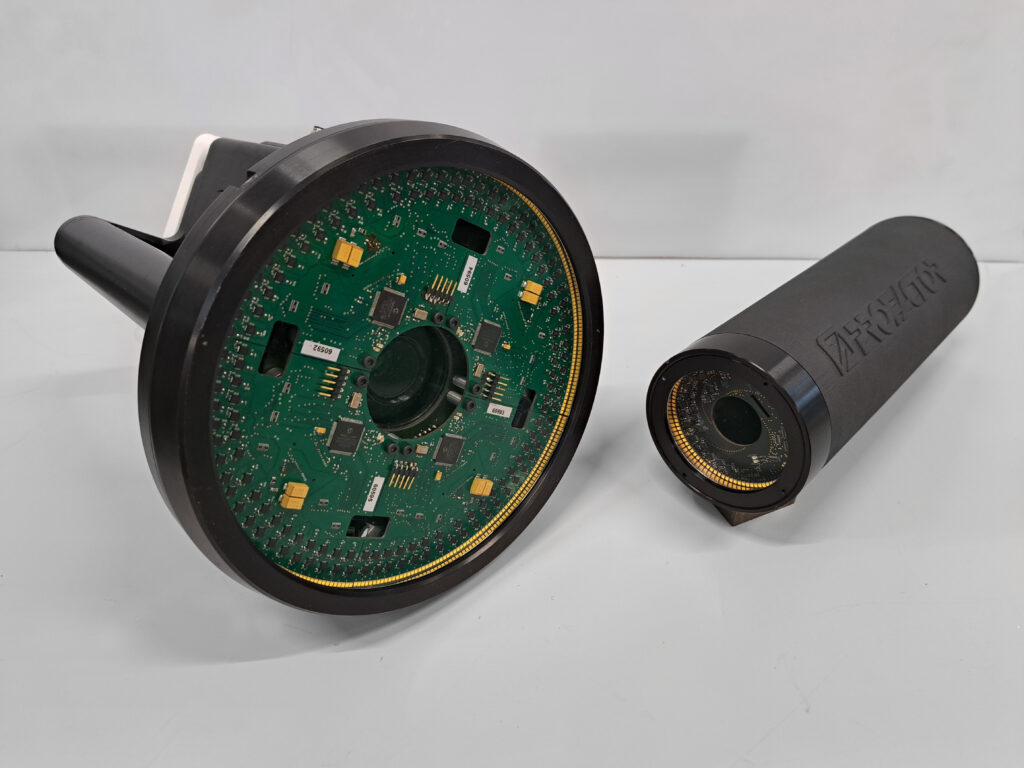

F-SCAN Compact

The compact design is smaller in size and therefore well suited for the inspection of parts with high curvature or in confined spaces. It is also better suited for the integration into handling systems for automatic draping and therefore enables inline quality control.

Resolution: 40-60µm

Measurement speed: 1m/s

Sensor diameter: 80 x 200mm

Sensor length: 200mm

Field of view: 25 x 25 mm

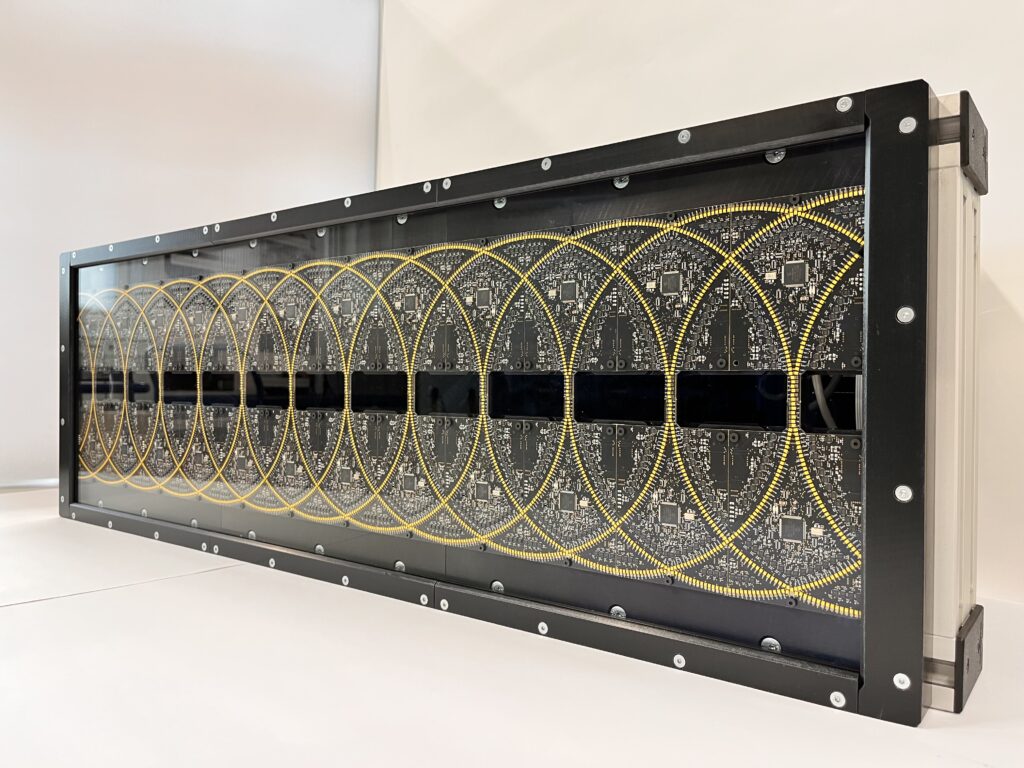

F-SCAN Wide

For the inspection of fabric a modular version of the sensor is available, which can be extended to a width of e.g. up to 2.5m (100″). This modular design allows its adaptation to any scanning width and can be integrated into weaving machines for inline quality control.

Resolution: 40-60µm

Measurement speed: 1m/s

Sensor width: 2500mm

Advantages

- Robust fiber orientation analysis

- Automated measurement on curved parts

- Integration of quality control with draping process (Inline inspection)

- Comparison with draping simulation

Wide range of materials

- Glass and carbon fabric

- Preforms and parts

- Non-crimp fabric (NFC) and woven materials

- Fabrics with or without sewing yarns

- Pre-preg material

Application areas

- Automotive

- Aerospace

- Lightweight construction

- Sports equipment, boat building