Highly flexible production and assembly lines with manual processes place heavy demands on quality control.

Products in varying configurations require full concentration and extensive knowledge from the employees on the line.

The Q-Station supports your employees intuitively:

- It recognizes each product on the conveyor belt and compares its condition with the orders from production planning.

- Article-related information is projected onto the moving products with pinpoint accuracy.

- Detected deviations trigger specific projections that actively alert employees to deficiencies.

- Sustainable efficiency and quality improvement even with a high number of variants and dynamic conveyor belt scenarios.

Use cases

- dynamic production environments

- highly flexible production, high product variety

- end-of-line quality control

- commissioning of complex products

- support for employee training

- digitalisation of the delivery status of all products

Successful in industrial use

This solution offers enormous flexibility and can be easily adapted to your environment.

Q-Station is successfully used in the international kitchen furniture industry on more than 10 production lines.

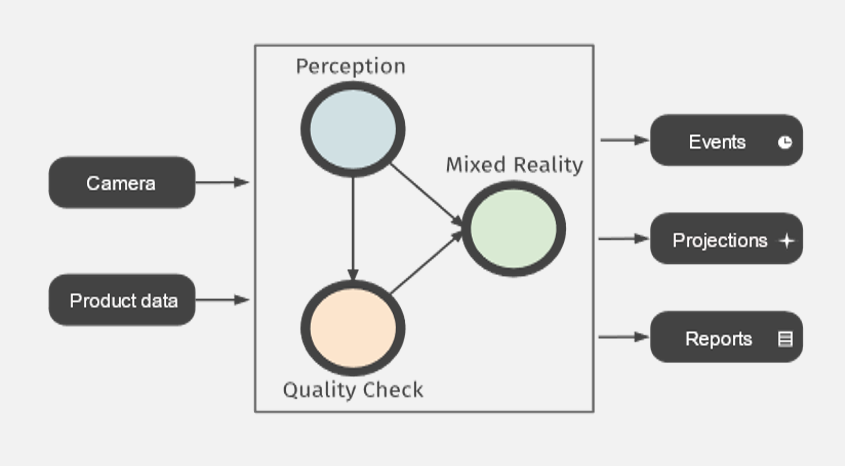

Innovative software components – the heart of Q-Station

Perception module

Identifies 3D positions of the items randomly placed on the assembly line, based on the raw data from the video camera.

Quality Check module

Examines specific characteristics of the products and performs quality checks based on the camera images.

Mixed Reality module

Processes 2D camera data and performs a 3D projection of cues directly onto the correct surface position of moving products.

What else you should know about Q-Station

No hardware signal needed

Q-Station does not require encoder signals from the conveyor belt and can therefore be implemented quickly and flexibly on a production line.

Integration of product data

Q-Station operates using stored product data.

Not only projections

Q-Station can automatically trigger further actions if required, from activating a warning lamp or text message notification to an autonomous belt stop.

Flexible use of hardware components

The system is based on robust standard hardware (PC, camera, projector), which is selected to fit the production environment (e.g. space availability, lighting).

Integrated into your look and feel

The design of the housing and the user interface can be individually adapted to the company’s requirements.

All products documented

Q-Station provides unique digital documentation of all your products for continuous quality improvement as well as to process any later complaints.